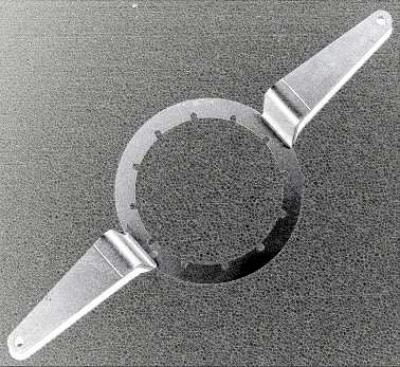

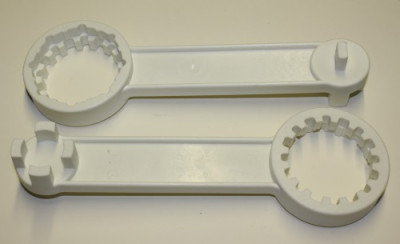

stainless steal wrench for montage screw cap DN 150

for SCHÜTZ and identical

Product.Nr.: RT00262-03790

Manufacturer: TÄSLER-IVP

82,11 EUR

incl. 19 % VAT

product description

stainless steal - special tool for screw cap DN 150 <br>for SCHÜTZ and identical

stainless steal V2A - VA 1.4301. , t = 5mm

EAN 0608819125084

GOOD TO KNOW

Stainless steel 1.4301 (V2A) is the first commercial stainless steel and is today with a production share of 33% of the most widely used stainless-steel. It is an austenitic, acid-resistant 18/10 Cr-Ni steel, which is intergranular due to its low carbon content after welding for sheet thicknesses up to 5 mm without subsequent heat treatment-resistant. He is admitted to a temperature of 600 ° C until use. At higher temperatures, the titanium-stabilized steel work should be to Mat. 1.4541 are used. The weldability is good for all electrical procedures, a gas welding should not be applied. The steel has a very good polishing ability and a particularly good ductility by deep drawing, bending, roll forming, etc. The cutting must be working because of the tendency to strain hardening of tools made of high speed steel or carbide.

Uses: The steel is resistant to water, steam, humidity, food acids and weak organic and inorganic acids and has a very diverse uses such as in the food industry, beverage production, pharmaceutical and cosmetic industry, chemical engineering, architecture, in the automotive industry, for household items and equipment, surgical instruments, in the bar and kitchen building, with toilets, for jewelry and art objects. The corrosion resistance is significantly increased by electropolishing. This is required especially in the pharmaceutical, food, medicine and facade engineering. The material is not stable in the presence of chlorine-containing media, such as salt water or chlorine-containing atmosphere in indoor swimming pools

Source: http://de.wikipedia.org

stainless steal V2A - VA 1.4301. , t = 5mm

EAN 0608819125084

GOOD TO KNOW

Stainless steel 1.4301 (V2A) is the first commercial stainless steel and is today with a production share of 33% of the most widely used stainless-steel. It is an austenitic, acid-resistant 18/10 Cr-Ni steel, which is intergranular due to its low carbon content after welding for sheet thicknesses up to 5 mm without subsequent heat treatment-resistant. He is admitted to a temperature of 600 ° C until use. At higher temperatures, the titanium-stabilized steel work should be to Mat. 1.4541 are used. The weldability is good for all electrical procedures, a gas welding should not be applied. The steel has a very good polishing ability and a particularly good ductility by deep drawing, bending, roll forming, etc. The cutting must be working because of the tendency to strain hardening of tools made of high speed steel or carbide.

Uses: The steel is resistant to water, steam, humidity, food acids and weak organic and inorganic acids and has a very diverse uses such as in the food industry, beverage production, pharmaceutical and cosmetic industry, chemical engineering, architecture, in the automotive industry, for household items and equipment, surgical instruments, in the bar and kitchen building, with toilets, for jewelry and art objects. The corrosion resistance is significantly increased by electropolishing. This is required especially in the pharmaceutical, food, medicine and facade engineering. The material is not stable in the presence of chlorine-containing media, such as salt water or chlorine-containing atmosphere in indoor swimming pools

Source: http://de.wikipedia.org